News

Discover the latest news about Extreema® soft slings.

Discover the latest news about Extreema® soft slings.

Discover the Extreema® soft sling range with high-performance lifting solutions tailored to meet the toughest demands across industries.

Extend the lifetime of slings with the Extreema® protections designed to safeguard your slings against cuts, abrasion, heat, and impact.

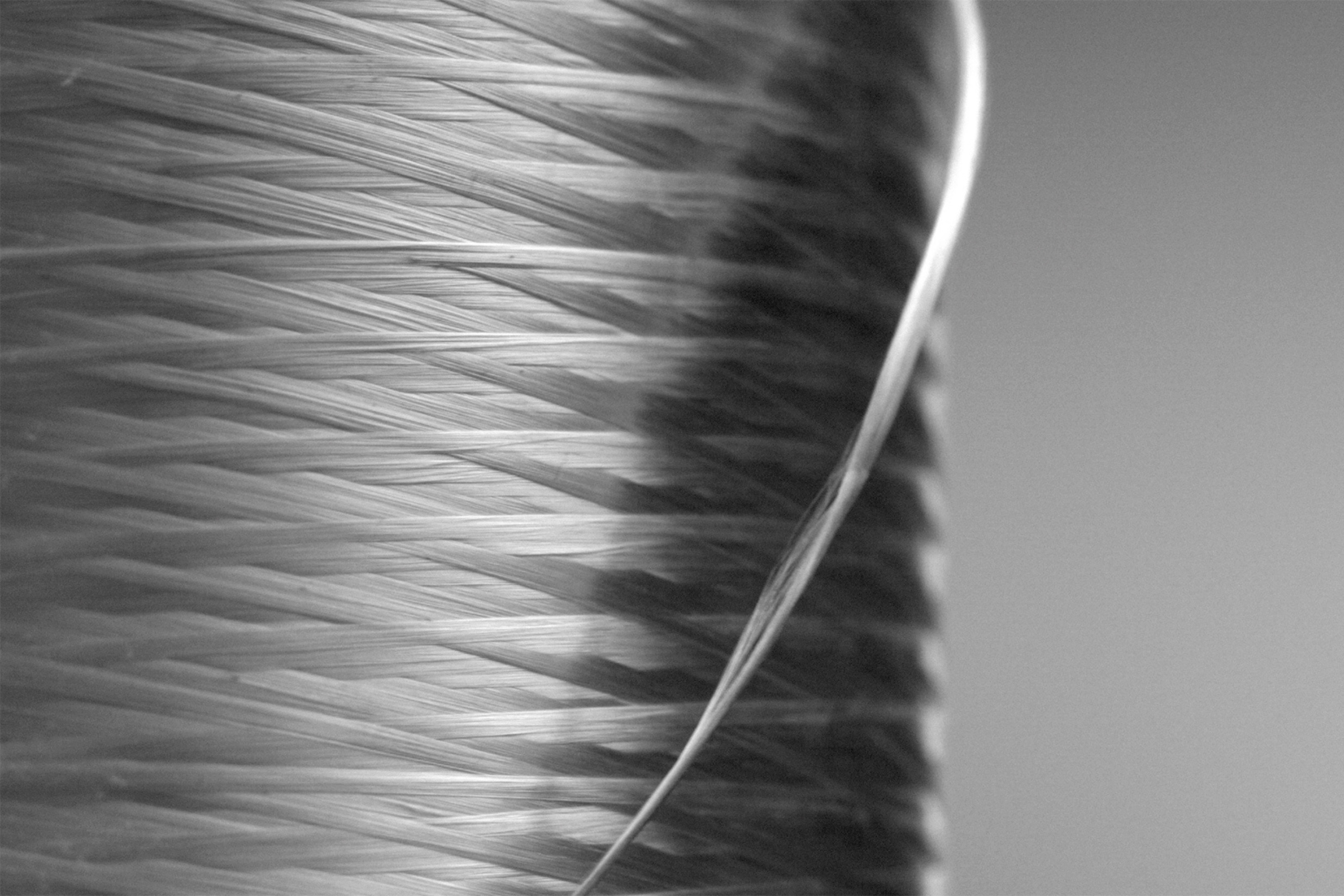

Extreema® soft slings are made with high-quality materials such as HMPE, (Bio-Based) Dyneema®, Cordura® and Polyester.