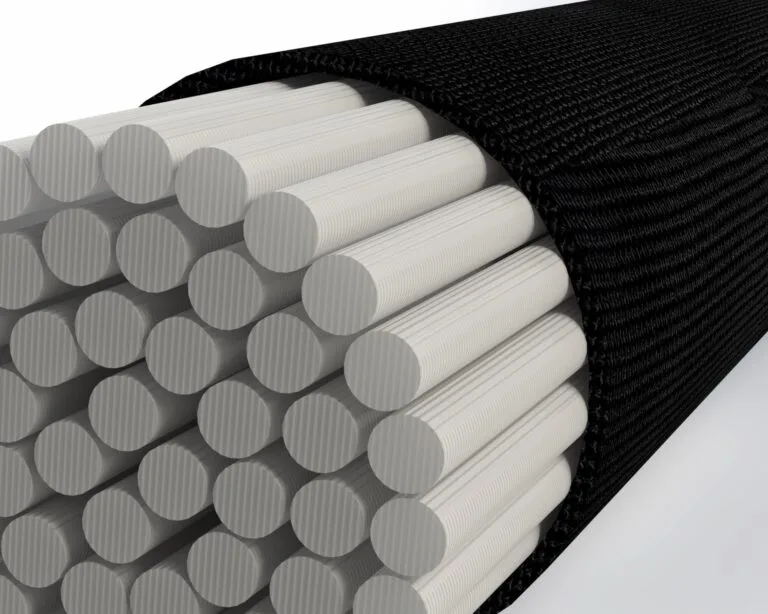

The Extreema® round slings are crafted with cutting-edge parallel-laid fiber technology, forming the very essence of their core. This remarkable core consists of an exclusive blend of 100% high-performance fibers, including the renowned Dyneema®, acclaimed as the world’s strongest fiber™, alongside Trosar® (general HMPE). These superior fibers ensure exceptional strength and durability, making Extreema® round slings an ideal choice for heavy-duty lifting and rigging applications.

Bio-Based Dyneema® Core

Bio-Based Dyneema® is an Ultra High Molecular Weight PolyEthylene (UHMWPE) known across the globe for its unparalleled strength-to-weight ratio. Developed by DSM in the Netherlands, this bio-based wonder fiber has earned the name “the world’s strongest fibre™”. With EU and US production facilities, Dyneema® yarn ensures a seamless fusion of accessibility and quality, catering to our esteemed customers’ global needs.

The secret behind Dyneema®’s superior performance lies within its remarkably elongated molecular chains. This design enables the efficient dispersion of loads across the polymer backbone, producing a fiber that redefines the boundaries of strength-to-weight optimization. Consequently, Dyneema® is the ultimate selection for high-performance ventures where strength and weight are critical factors. Count on Dyneema® to deliver exceptional feats, even amidst the most challenging conditions.

- Lightweight and flexible, easy to handle

- Less than 1% stretch at WLL, suitable for calculated lifts

- D:d = 1:1 for round slings up to 150T; above this D:d = 1:1,5

- Resistant against chemicals

- Does not absorb water

- Floats on water

- Long life cycle

- Bio-based

Aramid Core

Aramid is a synthetic fiber renowned for its outstanding strength and resistance to heat. Aramid fibers shine particularly in high-performance applications that demand remarkable durability. Aramid core is known for its high strength-to-weight ratio, exceptional cut resistance, and abrasion resistance. It is designed to excel even in demanding circumstances. Combining Aramid with other high-performance fibers results in a round sling that epitomizes strength, lightness, and adaptability. When facing the most demanding challenges, trust the Aramid core to consistently deliver reliable performance, making it the ideal choice for the most demanding applications.

HMPE Core

High-modulus PolyEthylene (HMPE) is a strong and durable material due to its long chains, which efficiently transfer loads and enhance interactions between molecules. This results in a rigid material with the highest impact strength of any thermoplastic.

HMPE is highly resistant to corrosive chemicals (excluding oxidizing acids), has low moisture absorption and friction, and is self-lubricating and abrasion-resistant. Although there’s limited long-term research, HMPE is manufactured to consistent quality standards by DSM in the Netherlands in Asia, making it reliable and high-performing in various applications.

Core

Features Comparison

| Dyneema | HMPE | Aramid | Polyester | |

|---|---|---|---|---|

| Price | €€€ | €€ | €€€ | € |

| Strength to weight ratio (cN/dtex) | 35,1 | 32,5 | 21,8 | 8,2 |

| Chemical resistance | Excellent (1) | Excellent (2) | Poor | Moderate |

| Temp. range (°C) | -180 – +70 (3) | -180 – +70 (3) | -70 – +200 (4) | -40 – +100 |

| Capacity range (MBL (metric ton)) (5) | 21 – 4200 | 21 – 4200 | 14 – 350 | 7 – 1400 |

| Length range (m) (6) | 0,5 – 65 | 0,5 – 65 | 0,5 – 65 | 0,5 – 65 |

| Specific gravity | 0,975 | 0,975 | 1,45 | 1,38 |

| Moisture resistance | Excellent (7) | Excellent (7) | Poor | Poor |

| Elongation at use (%) (8) | 0,5 – 1 | 0,5 – 1 | 0,6 – 1 | 3-5 |

| Elongation at break (%) | 3-4 | 3-4 | 4 | 10-14 |

1) Including extensive datasheets. Specific chemicals can be tested on request at yarn supplier.

2) Excluding extensive datasheets.

3) Strength decreases at higher temperatures. Max. temp for long exposure is 70 °C. More detailed info on request.

4) Remains full strength at max. temperature of 200 °C.

5) Capacity in straight pull configuration.

6) Length depending on WLL. Range is approximate. Higher/lower on specific request.

7) Does not absorb water.

8) Based on safety factor 7.