Core

Every Extreema® round sling is made exclusively with 100% high-performance fibers.

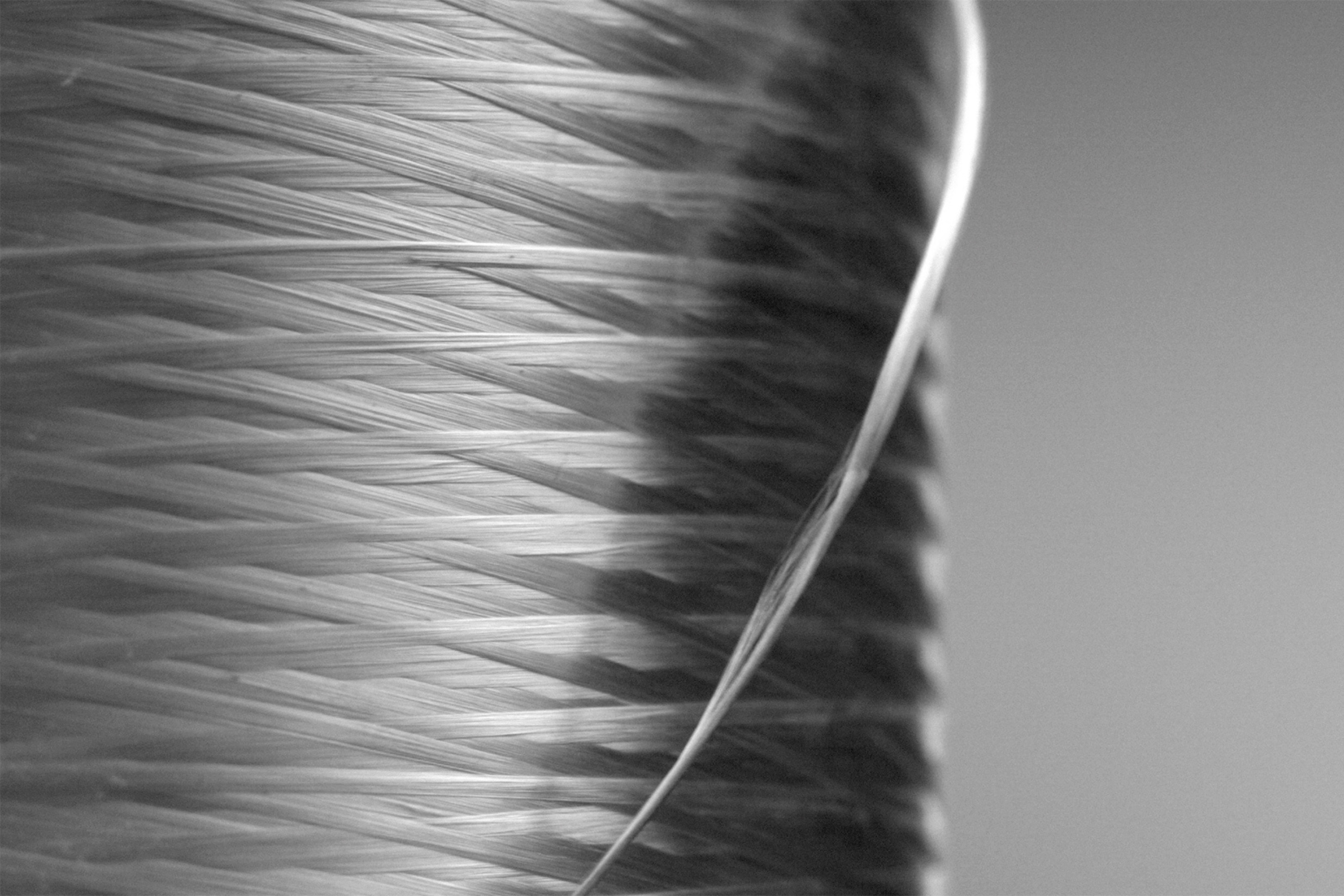

The Extreema® soft sling core

Extreema® soft slings are engineered using advanced parallel-laid fiber technology at their core, delivering unmatched strength and reliability. This innovative construction feature unique high-performance HMPE fibers, including the world-renowned Dyneema® known as the world’s strongest fiber™.

These ultra-strong materials provide exceptional durability and resistance to wear, making Extreema® round slings the optimal solution for heavy-duty lifting, rigging, and critical load-handling operations across industries like offshore, construction, and wind energy.

All Extreema® round sling series can be manufactured using the following high-performance materials:

- Dyneema®

- HMPE

- Aramid

Dyneema® core

Dyneema® is an Ultra-High Molecular Weight Polyethylene (UHMWPE) fiber, recognized globally for its unmatched strength-to-weight ratio. Developed by DSM in the Netherlands, this next-generation fiber is proudly known as “the world’s strongest fiber™.” With production facilities located in both the EU and the USA, Dyneema® ensures consistent supply, exceptional quality, and global availability for high-performance lifting and rigging applications. Lift-Tex® Heavy Lifting Slings is an official dealer of Dyneema®.

What makes Dyneema® unique is its extraordinarily long molecular chains, which distribute load efficiently across the polymer backbone. This unique molecular structure results in a fiber that pushes the limits of lightweight strength optimization, and making it the preferred choice for heavy-duty lifting, critical rigging, and demanding industrial environments where strength, safety, and weight reduction are essential.

- Extremely lightweight and flexible

- Minimal stretch <1% at Working Load Limit (WLL), ideal for calculated lifts

- High efficiency D:d ratio (1:1 for round slings up to 150T; 1:1.5 for heavier loads)

- Chemical-resistant

- Water-resistant

- Long service life

- Full dataset available

- Western origin (NL/US)

HMPE core

High-Modulus Polyethylene (HMPE) is a high-strength, lightweight fiber engineered for demanding lifting and rigging applications. Known for its exceptional durability, HMPE is composed of ultra-long molecular chains that efficiently transfer loads across the fiber structure. This unique composition results in a high-performance, load-bearing material with excellent impact strength, which makes it ideal for both dynamic and static load-bearing environments.

Although long-term aging data is still being developed, HMPE fibers are consistently manufactured to high-quality standards by trusted producers such as Avient in the Netherlands and various suppliers across Asia. This ensures reliable performance, traceability, and material consistency, even in the most challenging lifting applications.

Used as a core material in different Extreema® soft sling series, HMPE delivers a powerful balance of strength, flexibility, and cost-efficiency, making it a smart choice for all industries.

- Extremely lightweight and flexible

- Minimal stretch <1% at Working Load Limit (WLL), ideal for calculated precision lifts

- High efficiency D:d ratio (1:1 for round slings up to 150T; 1:1.5 for heavier loads)

- Chemical-resistant

- Water-resistant

- Long service life

Aramid core

Aramid core technology uses advanced synthetic fibers engineered for extreme performance. Known for their exceptional strength-to-weight ratio, superior heat resistance, and outstanding durability, aramid fibers are ideally suited for high-stress environments.

Specifically designed for the entertainment industry, aramid cores retain their structural integrity even in the demanding conditions of backstage environments.

As the core material in the Black Inferno® Sling, the aramid core ensures consistent performance, enhanced safety, and exceptional thermal resistance.

Aramid core technology utilizes advanced synthetic fibers engineered for extreme performance. Known for their exceptional strength-to-weight ratio, superior heat resistance, and outstanding durability, aramid fibers are ideal for high-stress environments.

- Ultra-light

- Exceptional cut and abrasion resistance

- Flexible

- Reliable performance under high temperatures

Core comparison

| Dyneema® | HMPE | Aramid | Polyester | |

|---|---|---|---|---|

| Price | €€€ | €€ | €€€ | € |

| Strength to weight ratio (cN/dtex) | 24,0 | 24,0 | 21,8 | 8,2 |

| Chemical resistance | Excellent (1) | Excellent (2) | Poor | Moderate |

| Temp. range (°C) | -180 -+ 70 (3) | -180 -+ 70 (3) | -70 -+ 200 (4) | -40 -+ 100 |

| Capacity range (MBL (metric ton)) (5) | 21 - 4200 | 21 - 4200 | 14 - 350 | 7 - 1400 |

| Length range (m) (6) | 0,5 - 65 | 0,5 - 65 | 0,5 - 8 | 0,5 - 65 |

| Specific gravity | 0,975 | 0,975 | 1,45 | 1,38 |

| Moisture resistance | Excellent (7) | Excellent (7) | Poor | Poor |

| Elongation at use (%) (8) | 0,5 -1 | 0,5 -1 | 0,6 -1 | 3 - 5 |

| Elongation at break (%) | 3 - 4 | 3 - 4 | 3,5 - 4,3 | 10-14 |

1) Including extensive datasheets. Specific chemicals can be tested on request at yarn supplier.

2) Excluding extensive datasheets.

3) Strength decreases at higher temperatures. Max. temp for long exposure is 70 °C. More detailed info on request.

4) Remains full strength at max. temperature of 200 °C.

5) Capacity in straight pull configuration.

6) Length depending on WLL. Range is approximate. Higher/lower on specific request.

7) Does not absorb water.

8) Based on safety factor 7.