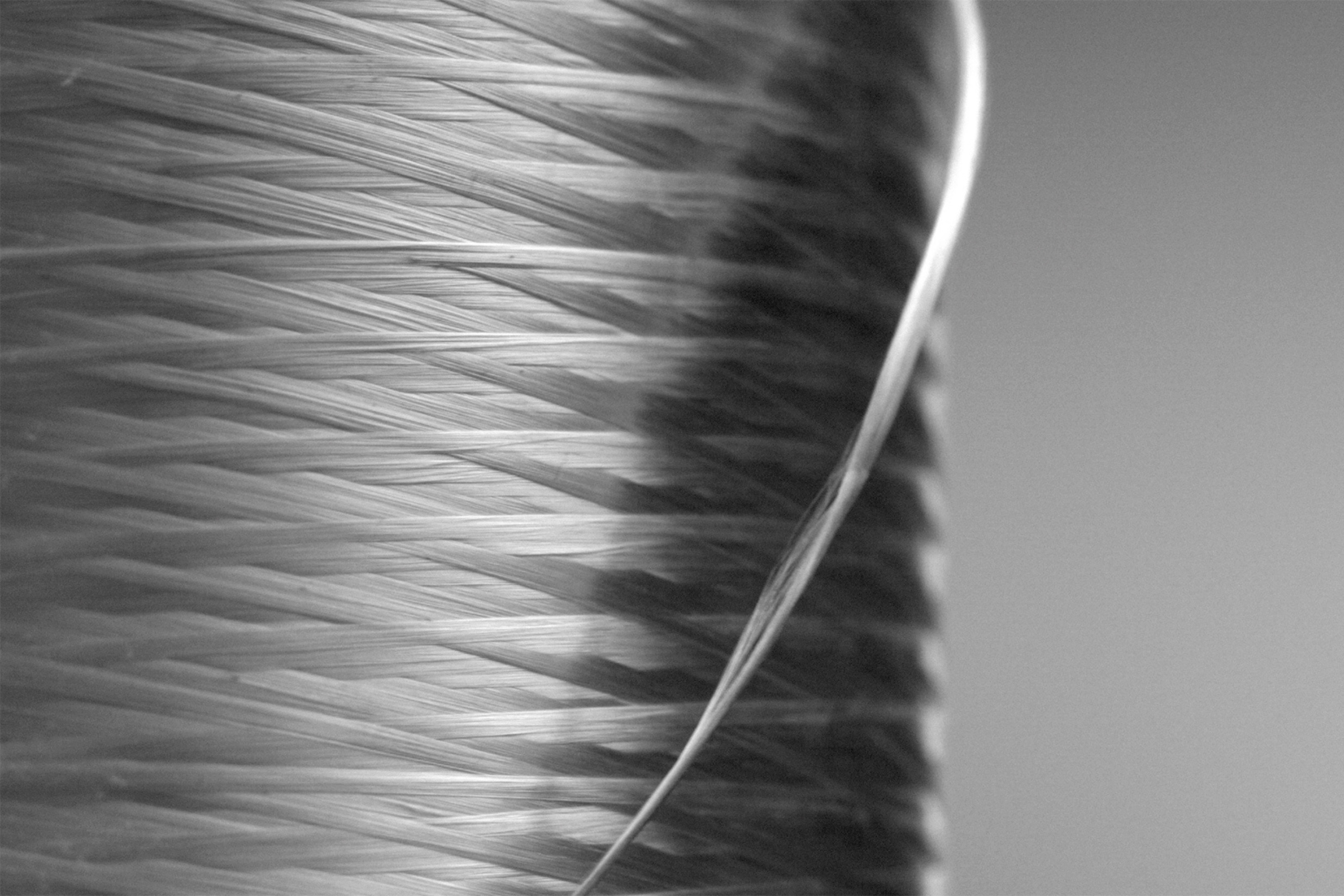

Signal sleeve

Easily identify sling damage, allowing safe use of the core with sleeve repair or replacement.

Signal Sleeves

In high-performance lifting applications, safety is non-negotiable. This is where the signal sleeve comes in. A smart, built-in safety feature designed to identify and indicate damage to a round sling its outer sleeve. Positioned around the core, this inner (warning) sleeve, made from bright red HMPE or high-visibility orange Polyester, acts as a clear visual indicator when the sling’s integrity might be damaged.

The signal sleeve eliminates guesswork by serving as an early alert system. When visible, it signals that the outer sleeve requires an thorough inspection. These inspections may confirm that the core remains safe for continued use, requiring only the outer sleeve to be repaired or replaced.

By implementing a signal sleeve, you not only reinforce lifting safety but also reduce unnecessary sling disposal, improving both operational efficiency and cost-effectiveness.

HMPE Signal Sleeve

Engineered for extreme durability, HMPE is renowned for its exceptional resistance to cuts, abrasions, and punctures which makes it the ideal material for safety-critical applications. In the event that a round sling its outer sleeve is damaged, the HMPE inner signal warning sleeve provides an essential layer of protection for the sling its core.

Manufactured in a vivid red color for maximum visibility, this inner sleeve acts as an highly visible indicator of damage. Its primary function is simple yet vital: alert users when the sling its functionalities may be at risk.

This built-in warning system supports faster safety assessments, enables timely sleeve repair or replacement, and ensures the core remains safe for continued use. By integrating the HMPE signal sleeve, you enhance workplace safety and extend the service life of your lifting equipment.

Polyester Signal Sleeve

As a practical alternative to HMPE, the Polyester inner signal warning sleeve offers a dependable safety solution for round slings. While it provides moderate resistance to cuts, abrasions, and punctures, it still plays a crucial role in enhancing lifting safety.

This sleeve is manufactured in a high-visibility orange color, making it easy to detect when the outer sleeve of the sling is damaged. When the orange sleeve becomes visible, it clearly signals that the sling’s outer layer may be damaged suggesting timely inspection, sleeve repair, or replacement, while allowing for safe continued use of the core.

Both HMPE and Polyester options are designed to support different performance needs while giving you the flexibility to choose the best solution based on your application, environment, and budget.

Sand Ingress Protection Filter

Extreema® soft slings are engineered for optimal performance in subsea environments, offering outstanding resistance against saltwater, chemicals, and moisture. These properties make them the go-to solution for demanding marine and offshore lifting operations.

However, even the toughest slings face specific challenges below the surface with one of the most common being internal abrasion caused dust and sand getting inside (the core) of the sling. To prevent this, Extreema® offers the Sand Ingress Protection Filter, a highly effective inner sleeve that safeguards the sling’s core from damaging particles.

The filter is designed with precision, featuring a fine O90 mesh opening of less than 0.036 mm, which efficiently blocks sand, dust and debris without restricting performance. This design ensures a perfect balance between protection and functionality, maintaining full sling performance while extending service life and reducing maintenance risk.

For subsea lifting applications where reliability is of high importance, the Extreema® Sand Ingress Protection Filter adds a critical layer of defense while keeping your lifting system clean, secure, and high-performing in the harshest underwater environments.